|

30 seconds summary

|

|

|

- Circuit breakers play a crucial role in outdoor power equipment by providing essential protection against electrical overloads and short circuits. They act as safety devices, automatically shutting off power when excessive current is detected, preventing damage to the equipment and reducing the risk of fire or injury.

- By interrupting the electrical flow during faults, circuit breakers help maintain the longevity of machinery and ensure safe operation in various outdoor environments.

- Understanding their function is key to maintaining reliable and safe power systems for outdoor activities.

|

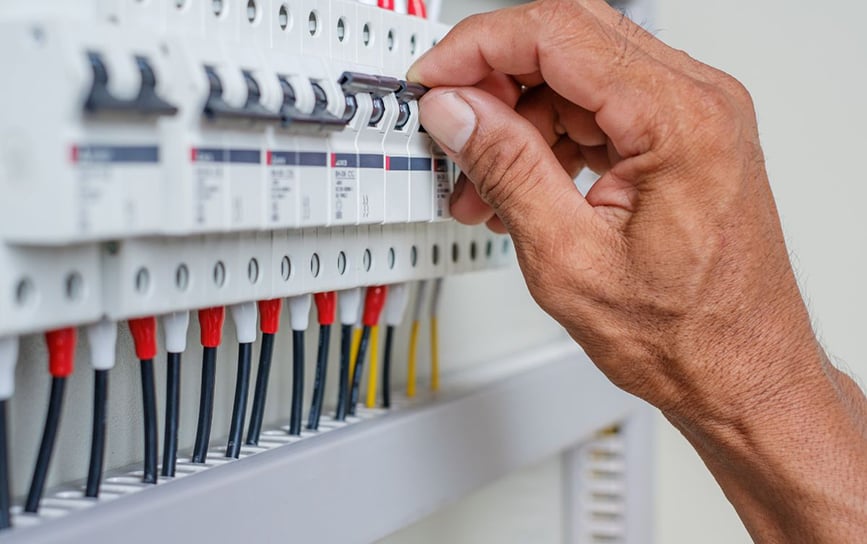

In the world of outdoor power equipment, safety and reliability are critical considerations. Whether used for lawn maintenance, construction, or other industrial applications, the equipment relies on electrical circuits to power their functions. These electrical circuits are vulnerable to overloads and short circuits, which can lead to serious damage or even pose a safety risk. This is where circuit breakers come into play. Circuit breakers are integral safety components that help prevent electrical hazards by interrupting the flow of electricity when an abnormal condition is detected.

Circuit breakers are designed to protect outdoor power equipment from electrical faults such as overloads, short circuits, and ground faults. They serve as a safeguard, ensuring that electrical components do not suffer damage due to excess current. This article aims to delve into the importance of circuit breakers in outdoor power equipment, their working principles, types, and applications, and how they contribute to the longevity and safety of these machines.

|

| The Importance of Circuit Breakers in Outdoor Power Equipment |

Circuit breakers are essential for protecting electrical systems in various outdoor power equipment, such as lawnmowers, snow blowers, generators, and pressure washers. In outdoor environments, electrical systems face several challenges, such as exposure to harsh weather conditions, fluctuating power supplies, and varying loads. Without a circuit breaker, outdoor power equipment could easily experience catastrophic failures due to power surges, overheating, or electrical faults.

The role of circuit breakers can be understood in the context of their basic function: to automatically detect and interrupt the electrical current when it becomes dangerous. By doing so, circuit breakers prevent damage to the electrical components of the power equipment, reduce the risk of fire hazards, and protect operators from electrical shocks.

|

| How Circuit Breakers Work |

To understand how circuit breakers contribute to the safety of outdoor power equipment, it is essential to grasp their operating principles. At their core, circuit breakers are designed to detect abnormal conditions in an electrical circuit and automatically break the circuit, stopping the flow of electricity. This is crucial because electrical faults such as overcurrent or short circuits can cause significant damage to equipment and present serious safety risks.

- Overcurrent Protection: When an electrical circuit is subjected to excessive current (overcurrent), the wiring and components in the circuit can overheat, leading to fires, equipment damage, or even explosions. Circuit breakers monitor the amount of current flowing through the circuit and, when the current exceeds a set threshold, the circuit breaker trips, opening the circuit and halting the flow of electricity.

- Short Circuit Protection: A short circuit occurs when there is an unintended low-resistance path formed between two conductors in the circuit. This causes a massive increase in current, which can damage the electrical equipment. Circuit breakers are specifically designed to detect short circuits and interrupt the current flow almost instantly, protecting the equipment from harm.

- Ground Fault Protection: Ground faults occur when electricity flows through an unintended path, such as a person or grounded surface. This is particularly dangerous in outdoor power equipment, as it can lead to electric shock. Ground fault circuit interrupters (GFCIs), a specialized type of circuit breaker, are often used in outdoor equipment to monitor and prevent dangerous ground faults.

|

Circuit breakers typically feature a mechanical switch that opens or closes the circuit depending on whether the current is within the acceptable range. The tripping mechanism in circuit breakers is based on either thermal or magnetic principles, or a combination of both.

- Thermal Circuit Breakers: These circuit breakers rely on a bimetallic strip that bends when heated by excessive current. As the strip bends, it triggers the release of a spring-loaded mechanism, opening the circuit and stopping the flow of electricity.

- Magnetic Circuit Breakers: Magnetic circuit breakers use an electromagnet to detect overcurrent conditions. When the current exceeds a certain level, the electromagnetic field becomes strong enough to trip the circuit breaker, instantly disconnecting the power.

- Thermomagnetic Circuit Breakers: Combining the thermal and magnetic principles, thermomagnetic circuit breakers offer enhanced protection by monitoring both the current flow and temperature.

|

| Types of Circuit Breakers Used in Outdoor Power Equipment |

Circuit breakers come in various types, each designed to suit different applications. The type of circuit breaker chosen for outdoor power equipment depends on factors such as the voltage and current ratings, the nature of the equipment, and the environmental conditions. Below are some common types of circuit breakers used in outdoor power equipment:

- Standard Circuit Breakers: These are the most common types of circuit breakers used in residential and commercial electrical systems. They are typically used in equipment such as generators, pressure washers, and other power tools. Standard circuit breakers are designed to protect against both overcurrent and short circuits.

- Ground Fault Circuit Interrupters (GFCIs): GFCIs are essential for outdoor power equipment, especially those used in damp or wet conditions. These circuit breakers detect ground faults, where current may flow to the ground through an unintended path, such as the human body. When a ground fault is detected, the GFCI trips and disconnects the power, helping to prevent electrocution.

- Arc Fault Circuit Interrupters (AFCIs): AFCIs are used in equipment that might be susceptible to arc faults. Arc faults occur when there is an electrical discharge, which can ignite nearby combustible materials and lead to fires. AFCIs monitor the circuit for signs of arcing and trip when an arc fault is detected.

- Magnetic Circuit Breakers: Magnetic circuit breakers are often found in applications requiring rapid response times, such as industrial power equipment. These breakers use an electromagnet to detect and react to overcurrent conditions almost instantly. They are frequently used in heavy-duty outdoor power tools and machinery.

- Hydraulic-Magnetic Circuit Breakers: These are specialized circuit breakers that combine hydraulic and magnetic principles to offer greater protection against both high and low current surges. They are used in equipment that requires higher precision and durability, such as large generators and industrial equipment.

|

| Applications of Circuit Breakers in Outdoor Power Equipment |

Circuit breakers are used in a wide range of outdoor power equipment to ensure safe operation and prevent electrical hazards. Some key applications include:

- Generators: Outdoor generators are often used to supply electricity in remote locations or during power outages. Because generators are exposed to various weather conditions and fluctuating electrical loads, they require circuit breakers to protect against overloads, short circuits, and other electrical faults. Without circuit breakers, a surge in current or a short circuit could damage the generator’s internal components.

- Lawnmowers: Lawnmowers, whether electric or gas-powered, use electric motors to drive the cutting blades. Circuit breakers in lawnmowers protect the motor and wiring from electrical faults. They also ensure that the mower operates efficiently and safely, preventing overheating and electrical failures.

- Pressure Washers: High-powered pressure washers rely on electric motors to generate water pressure for cleaning purposes. These machines are subject to heavy use and are often exposed to water, which increases the risk of ground faults and electrical short circuits. Circuit breakers, particularly GFCIs, are vital for protecting both the equipment and users from electrical shocks in these environments.

- Snow Blowers: Snow blowers operate in cold, wet conditions and are often used in harsh environments. These machines require circuit breakers to safeguard the electrical components from overloads and to ensure safe operation in potentially hazardous weather conditions.

- Power Tools: Outdoor power tools, such as chainsaws, drills, and hedge trimmers, often rely on circuit breakers for protection. Given the diverse range of tools used in outdoor environments, circuit breakers ensure that the equipment can handle fluctuations in power supply and avoid damage due to electrical faults.

|

| Benefits of Circuit Breakers in Outdoor Power Equipment |

The integration of circuit breakers into outdoor power equipment offers several significant benefits:

-

Enhanced Safety: The primary benefit of circuit breakers is enhanced safety. By automatically detecting electrical faults and disconnecting the power, circuit breakers reduce the risk of electrical fires, equipment damage, and electrical shock hazards. In outdoor environments, where conditions can be unpredictable, the role of circuit breakers becomes even more crucial.

- Improved Equipment Longevity: Circuit breakers help extend the lifespan of outdoor power equipment by preventing damage from overcurrent or short circuits. When a fault is detected, the breaker disconnects the circuit before any significant damage occurs, allowing the equipment to continue functioning properly.

- Preventing Downtime: By protecting outdoor power equipment from electrical damage, circuit breakers reduce the likelihood of downtime and the need for expensive repairs. This is especially important in industrial or commercial settings where power equipment is relied upon for productivity.

- Compliance with Safety Standards: Many countries have stringent safety standards for outdoor power equipment. The inclusion of circuit breakers ensures compliance with these standards and helps manufacturers meet regulatory requirements for electrical safety.

|

| Conclusion |

Circuit breakers are an essential component in the safety, efficiency, and reliability of outdoor power equipment. By protecting electrical circuits from overloads, short circuits, and ground faults, these devices ensure that outdoor power tools and machinery can operate safely in various conditions. Whether used in generators, lawnmowers, snow blowers, or power tools, circuit breakers play a vital role in preventing electrical hazards, extending the lifespan of equipment, and ensuring the safety of operators.

As technology continues to advance, the role of circuit breakers in outdoor power equipment will become even more critical. With the increasing use of electronic controls, smart sensors, and automated systems, circuit breakers will continue to evolve, providing more sophisticated and reliable protection for outdoor power equipment. Ultimately, circuit breakers are not just safety devices; they are integral components that help maintain the efficient and safe operation of outdoor power equipment in an increasingly complex and dynamic environment.

|